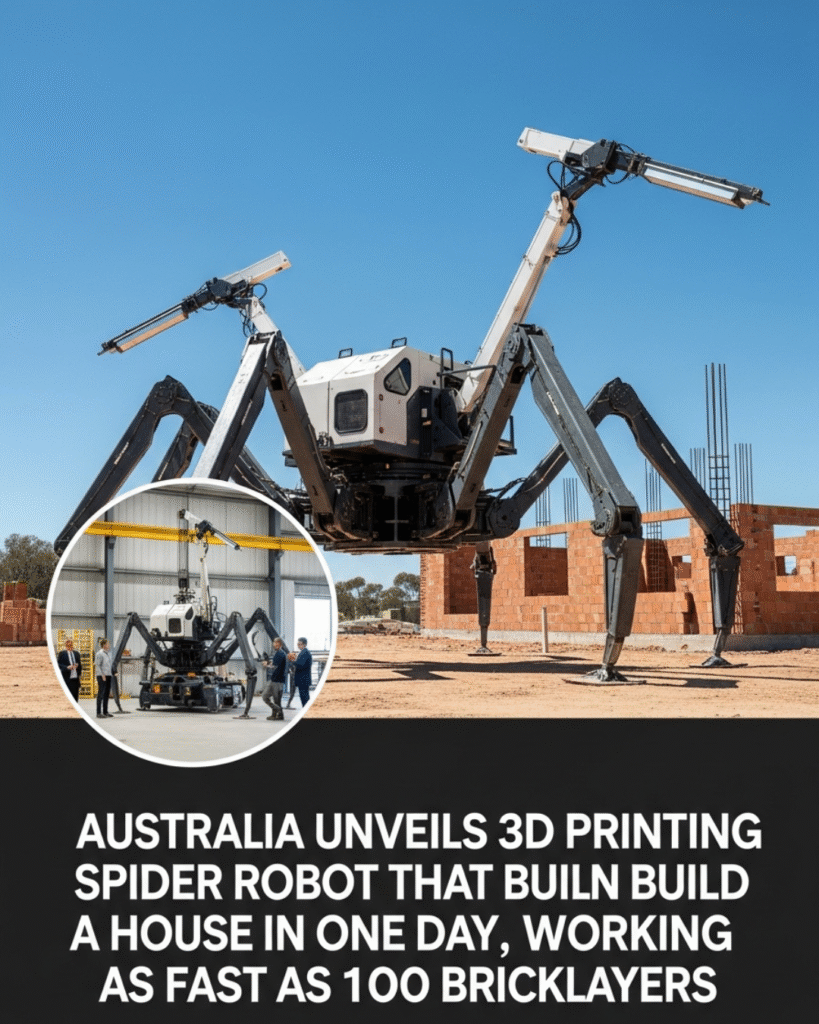

In construction sites across the globe, a technological revolution is quietly unfolding. Advanced robotic systems equipped with 3D printing capabilities are demonstrating the potential to erect complete residential structures in timeframes that challenge conventional building methodologies. These spider-like autonomous machines, operating with coordinated precision, promise to transform the construction industry by accomplishing in hours what traditional methods require weeks to complete.

What Are 3D Printing Spider Robots and How Do They Function in Construction?

The emergence of spider-configuration robotic construction systems represents a convergence of additive manufacturing, autonomous navigation, and structural engineering. These machines derive their arachnid nomenclature from their multi-limbed architecture, typically featuring six to eight articulated appendages that provide exceptional stability and mobility across uneven terrain.

At the core of these systems lies a sophisticated extrusion mechanism capable of depositing construction materials—primarily specialized concrete mixtures, composite polymers, or fiber-reinforced compounds—in precise, predetermined patterns. The robotic platforms integrate real-time sensing arrays, including LIDAR scanners, stereoscopic vision systems, and inertial measurement units, enabling them to navigate construction sites autonomously while maintaining millimeter-level positional accuracy.

The operational paradigm differs fundamentally from conventional construction. Rather than assembling discrete components, these robots construct structures through continuous material deposition, building walls layer by layer in a process analogous to biological tissue formation. The extruded material, engineered for rapid curing, achieves structural integrity within minutes of deposition, allowing subsequent layers to be added in continuous succession.

Contemporary prototypes employ advanced computational architectures that process building information modeling (BIM) data, translating architectural designs into executable motion paths. Machine learning algorithms optimize deposition parameters in real-time, adjusting for environmental variables such as temperature, humidity, and wind velocity—factors that significantly influence material behavior during the curing phase.

How Does the Speed Compare to Traditional Bricklaying Methods?

The quantitative analysis of construction velocity reveals striking disparities between robotic and manual methodologies. Traditional bricklaying, performed by skilled craftsmen, typically achieves rates of 300 to 500 bricks per day per worker under optimal conditions. This throughput reflects not merely the physical act of placement but encompasses mortar preparation, alignment verification, and quality control procedures.

In contrast, advanced robotic printing systems demonstrate material deposition rates exceeding 2,000 kilograms per hour. When translated to volumetric output, a single spider robot can extrude sufficient material to construct approximately 100 square meters of wall surface in an eight-hour operational period. This performance effectively parallels the combined output of 80 to 100 traditional bricklayers working simultaneously—a remarkable efficiency multiplier.

The temporal advantages extend beyond raw speed. Conventional construction suffers from inherent discontinuities: workers require breaks, shifts conclude, and adverse weather conditions frequently halt operations. Robotic systems, conversely, maintain consistent output across extended periods, operating continuously provided adequate material supply and power infrastructure exist. Certain advanced prototypes incorporate predictive maintenance algorithms that schedule component replacements during optimal windows, minimizing unplanned downtime.

Furthermore, the spider robot architecture enables parallel processing strategies. Multiple units can collaborate on a single structure, each addressing different sections simultaneously while sophisticated coordination protocols prevent interference and ensure structural continuity at connection points. This distributed approach compounds efficiency gains, potentially reducing construction timelines from weeks to single-day durations for modest residential structures.

Which Technological Components Enable Rapid Autonomous Construction?

The technical ecosystem supporting rapid robotic construction integrates multiple sophisticated subsystems, each contributing essential capabilities to the overall functionality. The material delivery system constitutes perhaps the most critical element—advanced pumping mechanisms maintain consistent flow rates and pressures, ensuring uniform extrusion characteristics across varying environmental conditions.

Proprietary concrete formulations represent significant innovations in their own right. These specialized mixtures incorporate accelerating admixtures, rheology modifiers, and fiber reinforcements that provide optimal printability while achieving rapid strength development. Some formulations attain 70% of design strength within 24 hours, compared to the 28-day curing period required by conventional concrete.

The robotic locomotion system employs hydraulic or electromechanical actuators coupled with advanced control algorithms that maintain stability across uneven substrates. Certain designs incorporate adaptive feet mechanisms that automatically adjust to terrain irregularities, while others utilize tracked or wheeled configurations optimized for construction site mobility.

Navigation and positioning rely on sensor fusion techniques that integrate data from multiple sources. GPS systems provide coarse positioning, while local sensing modalities—ultrasonic rangefinders, laser scanners, and computer vision systems—enable precise relative positioning. Advanced implementations employ simultaneous localization and mapping (SLAM) algorithms, allowing robots to construct detailed environmental models while determining their position within those models.

The computational substrate orchestrating these components typically comprises distributed processing architectures. Edge computing nodes handle time-critical control loops and sensor processing, while cloud-connected systems manage higher-level planning, design optimization, and fleet coordination for multi-robot deployments.

What Materials and Structural Approaches Do These Systems Employ?

Material science innovations underpin the feasibility of rapid robotic construction. Traditional construction materials often prove incompatible with additive manufacturing processes, necessitating the development of specialized formulations that balance printability, structural performance, and economic viability.

Cementitious composites dominate current applications, typically comprising Portland cement, fine aggregates, supplementary cementitious materials such as fly ash or silica fume, and proprietary additive packages. These mixtures exhibit pseudo-plastic rheological behavior—remaining fluid under the shear forces encountered during pumping and extrusion, yet rapidly developing sufficient yield strength to support subsequent layers without deformation.

Geopolymer alternatives are gaining traction, offering reduced carbon footprints compared to traditional cement-based systems. These materials derive binding properties from aluminosilicate reactions rather than Portland cement hydration, potentially reducing embodied CO2 emissions by 60-80%. Their rapid setting characteristics prove particularly advantageous for robotic construction applications.

Fiber reinforcement strategies enhance structural performance without requiring traditional steel reinforcement cages. Synthetic fibers—polypropylene, polyethylene, or glass—distributed throughout the matrix provide multidirectional reinforcement and control shrinkage cracking. Some advanced systems incorporate continuous fiber placement, where carbon or basalt fiber tows are embedded within the printed material, creating optimized load paths that align with structural stress patterns.

The geometric freedom afforded by additive manufacturing enables novel structural configurations. Rather than relying on solid walls, some designs employ honeycomb infill patterns or topology-optimized geometries that minimize material usage while maintaining structural adequacy. These approaches can reduce material consumption by 30-50% compared to conventional construction while simultaneously improving thermal insulation properties through the introduction of air-filled cavities.

How Do Spider Robots Address Structural Integrity and Building Codes?

The integration of robotic construction technologies within existing regulatory frameworks presents complex challenges. Building codes, developed over decades to ensure occupant safety within traditionally constructed buildings, often lack explicit provisions for additively manufactured structures. This regulatory lacuna necessitates case-by-case evaluation and approval processes that can significantly extend project timelines.

Structural performance validation relies on comprehensive testing protocols that characterize material properties and structural behavior. Researchers conduct extensive laboratory investigations, subjecting printed specimens to compression, tension, flexure, and bond strength testing. These evaluations generate data that enable engineers to develop appropriate design parameters and safety factors.

Interface bonding between successive layers represents a critical consideration. Unlike monolithic cast concrete, printed structures exhibit anisotropic properties—strength characteristics vary depending on the orientation relative to layer deposition direction. The interlayer bond strength typically governs structural capacity, particularly under tensile or shear loading. Advanced printing protocols address this limitation through surface preparation techniques, optimized layer timing to maximize chemical bonding, and mechanical interlocking strategies that create irregular interface geometries.

Quality assurance methodologies adapted for robotic construction employ real-time monitoring systems. Thermal imaging cameras track temperature evolution during curing, identifying anomalies that might indicate inadequate material mixing or placement errors. Acoustic emission sensors detect internal cracking or delamination. Some systems integrate non-destructive testing capabilities directly into the robot platform, enabling immediate verification of each deposited layer.

Seismic performance constitutes a particular concern in earthquake-prone regions. The ductility and energy dissipation capacity of printed structures differ from conventionally reinforced concrete. Ongoing research investigates hybrid approaches that combine printed wall systems with traditional reinforced concrete frames or post-tensioning systems to achieve adequate seismic resistance.

Which Economic and Environmental Factors Drive Adoption?

The economic calculus surrounding robotic construction technologies encompasses multiple dimensions extending beyond simple labor cost comparisons. While eliminating substantial manual labor represents an obvious advantage, comprehensive analysis must consider capital equipment costs, material expenses, energy consumption, and maintenance requirements.

Current robotic systems require significant capital investment, with advanced platforms costing between $500,000 and $2 million. However, amortization across numerous projects can render these costs competitive with traditional methods, particularly in markets experiencing labor shortages or elevated wage rates. Economic models suggest breakeven points ranging from 15 to 30 residential units, depending on local construction costs and project complexity.

Material costs present a more nuanced picture. Specialized printable formulations typically command premium pricing compared to conventional concrete, potentially offsetting labor savings. However, the precision of robotic deposition minimizes material waste, a significant consideration given that conventional construction typically generates 10-15% material excess. Additionally, topology optimization capabilities enable structures that employ 30-50% less material while maintaining equivalent performance, potentially yielding net material cost reductions.

Environmental considerations increasingly influence construction methodology selection. The building sector accounts for approximately 39% of global CO2 emissions, with cement production alone contributing 8%. Robotic construction offers multiple pathways toward emissions reduction: minimized material usage through optimized geometries, enablement of low-carbon alternative binders, elimination of formwork (which often employs energy-intensive materials), and reduced transportation requirements through potential on-site material production.

Energy consumption analysis reveals that robotic systems typically consume 40-60 kilowatt-hours per cubic meter of deposited material, encompassing pumping, extrusion, and locomotion. While non-trivial, this figure compares favorably to the embodied energy in traditional construction when accounting for material production, transportation, and placement activities.

The social dimension merits consideration. Concerns arise regarding labor displacement in construction sectors that provide employment for millions globally. Proponents counter that robotic systems will complement rather than replace human workers, handling repetitive, physically demanding tasks while humans focus on skilled activities including design, quality supervision, finishing work, and system maintenance.

What Are the Current Limitations and Technical Challenges?

Despite remarkable progress, numerous technical and practical obstacles impede widespread robotic construction adoption. Scale limitations represent a primary constraint—most demonstrated projects involve single-story residential structures with relatively simple geometries. Extending capabilities to multi-story buildings requires addressing challenges related to vertical reach, platform stability, and material supply logistics.

Integration of building systems presents considerable complexity. While robots excel at creating structural shells, conventional buildings incorporate numerous additional components: electrical conduits, plumbing networks, HVAC systems, windows, doors, and interior finishes. Current robotic platforms lack the dexterity and adaptability required for these varied tasks. Hybrid approaches combining robotic structural construction with traditional installation of building systems represent the prevailing paradigm, limiting overall time savings.

Material performance under diverse climatic conditions requires further investigation. Most demonstrations occur in controlled or temperate environments. Extreme temperatures, high humidity, or precipitation significantly affect material behavior during deposition and curing. Developing robust formulations and adaptive printing protocols that maintain performance across varied environmental conditions remains an active research frontier.

Customization and architectural complexity pose algorithmic challenges. While these systems excel at repetitive tasks, accommodating client-specific modifications or intricate architectural features requires sophisticated path planning and potentially manual intervention. The computational complexity of generating collision-free motion paths for multi-robot systems operating in constrained spaces grows exponentially with geometric intricacy.

Quality control and defect detection methodologies lag behind production capabilities. Unlike manufacturing environments where dimensional tolerances measure in micrometers and comprehensive inspection protocols exist, construction traditionally accepts millimeter-level variations and employs visual inspection. Developing appropriate standards, measurement techniques, and acceptance criteria for printed construction represents an ongoing challenge.

The skilled workforce required to operate, maintain, and supervise these systems remains limited. Effective deployment requires personnel with interdisciplinary expertise spanning robotics, materials science, and construction engineering—a rare combination. Educational institutions are beginning to develop relevant training programs, but workforce development will require years to mature.

How Might This Technology Evolve and Impact Future Construction?

The trajectory of robotic construction technology suggests transformative potential extending well beyond efficiency improvements. Emerging research explores multi-material printing capabilities that would enable seamless integration of functional materials—thermal insulation, vapor barriers, and even structural reinforcement—within a single continuous process. Such capabilities could eliminate numerous discrete construction steps, further compressing timelines while improving building performance.

Autonomous planning systems leveraging artificial intelligence may soon enable direct translation from high-level design intent to executable construction sequences, eliminating time-consuming programming phases. Machine learning algorithms trained on thousands of construction projects could optimize designs for manufacturability, cost, and performance simultaneously, exploring design spaces too vast for manual consideration.

Extraterrestrial applications capture significant research interest. The challenges of construction in lunar or Martian environments—extreme temperatures, radiation exposure, limited material availability—align well with robotic construction capabilities. Several space agencies are investigating in-situ resource utilization approaches that would employ local regolith as feedstock for 3D printing habitats, potentially enabling sustainable off-world human presence.

The democratization of construction represents a profound social implication. As systems mature and costs decline, technologies currently accessible only to well-funded research programs or large construction firms may become available to smaller contractors or even individuals. This accessibility could enable rapid disaster relief housing, affordable housing in underserved markets, or realization of highly customized architectural visions previously constrained by economic limitations.

Integration with broader digitalization trends in construction—building information modeling, digital twins, sensor networks for performance monitoring—positions robotic construction within an emerging ecosystem of intelligent, adaptive built environments. Structures might incorporate embedded sensors deployed during construction, enabling lifecycle monitoring and informing future design iterations through data-driven feedback loops.

The convergence of robotic construction with sustainable materials innovation could address pressing environmental imperatives. Systems capable of processing bio-based materials, recycled aggregates, or carbon-sequestering formulations would contribute meaningfully to decarbonizing the built environment while maintaining the productivity advantages of automated construction.

The advent of spider-configured 3D printing robots capable of constructing residential structures in dramatically compressed timeframes represents more than incremental technological progress—it embodies a fundamental reimagining of construction methodologies. These systems, achieving output equivalent to hundreds of skilled tradespeople, demonstrate that the integration of advanced robotics, materials science, and computational design can transcend longstanding productivity constraints that have characterized the building sector.

While significant technical, regulatory, and economic challenges remain before such technologies achieve mainstream adoption, the demonstrated capabilities and ongoing research trajectory suggest that robotic construction will play an increasingly prominent role in addressing global housing needs, disaster response requirements, and sustainability imperatives. The transformation from experimental curiosity to established construction methodology will require continued interdisciplinary collaboration, thoughtful regulatory evolution, and sustained investment in both technology development and workforce preparation. As these elements converge, the vision of structures rising in hours rather than months transitions from aspiration to achievable reality.